By Jeff Yowell

Business Development Executive

Here's what we'll cover:

Metal nameplates, also known as equipment nameplates, aren’t typically top-of-mind in people’s daily use of vehicles, home appliances, and the other products to which nameplates are commonly affixed.

Even though they might not seem like the most engaging part of your branding, your nameplates play a vital role in keeping your products legally compliant with state and federal law while making sure your customers have the product and safety information they need.

Beyond their informational and legal uses, however, nameplates serve a much more important purpose in your marketing arsenal: They create strong emotional connections between you and your customers that make them loyal users of your products, bolster industry reputation, and set you apart from your competition.

Whether you’re a seasoned veteran of the product identification industry, or you’re new to the concept of nameplates as a whole, don’t worry. You’re in the right place and we’re going to explain every detail of how impactful your nameplates truly are.

So let’s dive in and discover the purpose of nameplates, understand their impact on customers, and learn how you can select a nameplate that keeps customers safe, ensures any legal requirements are fulfilled, and how your product identification is a powerful tool to promote your brand’s authority and reputation.

What is Product Identification?

Product identification is a broad field consisting of informational products and tools, such as labels, decals, panel overlays, nameplates, and other items that help brands keep track of their products, prevent theft, and amplify their branding while conveying important information to customers.

What is the Purpose of a Metal Product Identification Nameplate?

Make no mistake — while they might be a great part of your visual branding arsenal, your nameplates have a job to do.

While the specific requirements of product identification within your industry might vary depending upon your product, effective nameplates should fulfill the following critical functions:

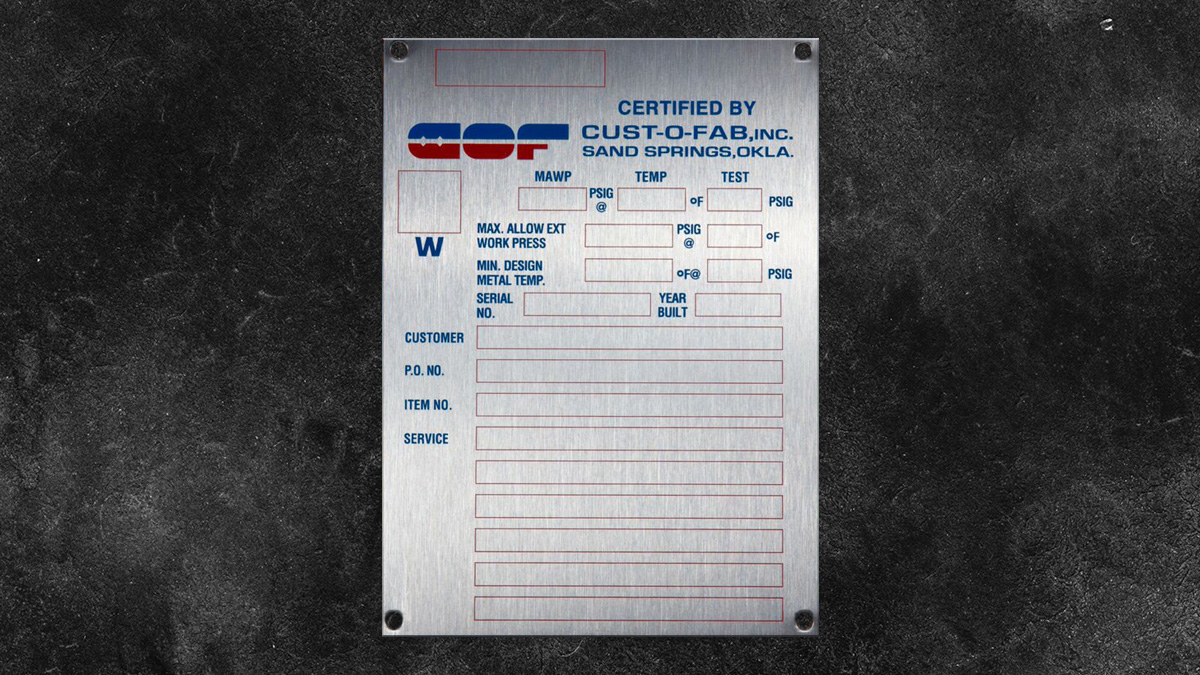

Nameplates provide the product tracking information your industry or country may mandate.

One of the chief purposes of metal nameplates is to ensure your product has all of the industry-mandated and legally-required information prominently displayed.

This typically includes information such as identification numbers, tracking codes, manufacturing dates, and more which helps your customers, industry oversight bodies, and law enforcement ensure your products are authentic and compliant with all regulations.

Additionally, with the ever-increasing prevalence of automation, your nameplates also provide data to the robotics that might be present in some of the manufacturing or shipping points on your path to your customer.

Nameplates clearly communicate all information your customer needs to use your product correctly and safely.

When a customer or operator of your equipment is needing immediate insight on how to use your product, one of the first places they look to is the labeling.

Here, with the information properly displaying the relevant information they need, they can safely execute the tasks they need to get done.

But without it, it’s not just the end-user who’s at risk — your brand is too.

Lacking that safety or instructional information, your brand is at risk of not only violating regulation, but you’re also at risk of opening your company up to a lawsuit if that end-user — or others — is injured while using your product.

By investing in quality nameplates that meet the needs of your customers and the environments they’ll be facing, you invest in the longevity of your brand’s reputation, the safety of your customers, and help protect yourself from costly litigation.

Nameplates help guard against counterfeiting and theft.

The presence of a nameplate is a strong deterrent against would-be thieves.

By clearly displaying the information used to automatically track your products’ shipping and manufacturing, would-be thieves think twice before stealing your goods, as they have to consider the risk of taking something that’s so easily traceable.

And when your product nameplates are a known part of your company’s consistent visual branding, people know something’s fishy when they’re missing. Here, your branded nameplates effectively kill the customer markets that thieves might target, as anyone they look to sell to will be able to notice that the tracking data or product information plates are missing.

What Metal Substrates are Commonly Used in Metal Nameplates?

A “substrate” is the underlying material upon which your product identification nameplate is embossed, etched, engraved, or otherwise marked.

Let’s take a look at some of the more common choices of substrate, what makes them unique, and how they might affect the look and performance of your nameplate.

Aluminum

Aluminum is one of the more popular choices of substrate, due to its unique blend of natural durability and resistance to a broad range of chemicals and weather conditions.

While not as strong as stainless steel — one of the other leading nameplate substrates — it’s far more malleable, lightweight, and is the cheaper option in most circumstances.

If you’re just getting started on your journey into choosing a metal nameplate for your durable goods, odds are that aluminum is the cost-effective fit that will meet your needs.

Anodized Aluminum

Every piece of aluminum naturally forms an air-tight oxide coating on its surface when it’s exposed to the oxygen in the air. However, by exposing this oxide layer electrochemically — through the process called “anodization” — we exponentially increase the overall utility of the aluminum.

This makes the aluminum far more durable, corrosion-resistant, and less prone to abrasion. But what’s especially exciting about the process is how dyes can be applied during the electrochemical processes and tightly bond within the oxide layer, creating seamless on-brand color.

If you’re aiming to maximize the attention your nameplate receives or complement the colors in your branding, anodized aluminum is a great choice.

Brass

Brass provides the perfect mixture of style and function. As one of the “red metals” alongside copper and bronze, it possesses a few unique qualities that aren’t found in other alloys commonly used in product identification nameplates.

First among these unique properties is brass’s inability to create a spark, due to the lack of ferrous metals — such as iron or steel — within them. This makes brass a great fit for product nameplates that might be exposed to environments where sparks might prove dangerous or even fatal, such as in plumbing or electrical work.

Most interestingly of all, brass is naturally antibacterial, killing up to 99.9% of all bacteria within 2 hours of contact.

Here, brass perfect for nameplates on products used within the foodservice or healthcare industries, as it naturally complements their high sterility requirements.

Stainless Steel

For most industries, stainless steel is the go-to choice for nameplate substrates, due to its unmatched strength and its ability to withstand extreme conditions.

Be it biting cold or intense heat, it’s high durability and ability to withstand rapid shifts in temperature without warping or degrading ensures the information you need to display is always clearly legible.

And given stainless steel’s non-porous structure, it’s corrosion resistance is unmatched, making it the perfect choice for nameplates for products that come in regular contact with caustic chemicals.

Needing nameplates in a different alloy or material? We’ve got you covered.

Contact Our ExpertsWhat Should You Consider When Selecting a Substrate for a Metal Nameplate?

When selecting the right substrate for your product identification nameplates, it’s good to know the unique strengths and weaknesses of the materials like the ones we covered.

But to make sure your dollars are spent effectively, we always work with our customers to make sure they know the answers to the following key questions.

What industries does your product or machinery serve?

When you’re first getting started selecting a substrate, it’s best to consider the end-users of your product and the environments they’ll be facing, how your product will be stored, and how the information you print on your nameplate is relevant to their work.

What chemicals might interact with your metal nameplate?

If you’re choosing a substrate that will be used in or around chemicals, it’s best to favor alloys that are highly corrosion resistant, such as stainless steel. However, should your product be used in a highly specialized environment wherein the exact chemicals are known in advance, the alloy of your nameplate should work to withstand those conditions.

What environments or weather conditions will your nameplate encounter?

While cost-effective solutions like aluminum are always attractive due to their budget-friendliness and all-around ease of application, it’s important to consider how your substrate will stand up to the test of time.

Your product may be used to handle a specific task, but how it’s stored by your customers and the weather environments that they expose it to can degrade your nameplate over time.

What legal requirements does your industry enforce on nameplates?

Many industries have strict regulations regarding how nameplates are placed on products, what information they must contain, and even what properties — such as corrosion-resistance — your nameplates must possess.

Before choosing your substrate, consult with the governing bodies and official authorities of your industry to ensure your choice of alloy is in full legal compliance.

What’s the Difference Between Etching, Engraving, and Embossing Your Product Identification Nameplates?

Much like your choice of substrate, the methods by which your nameplates are marked is an important decision that affects the overall quality of the nameplate and your customers’ ability to access the information they need.

Etched Nameplates: Acid Etching & Laser Etching

Etching is the process of vaporizing a thin top layer of your substrate, thus producing highly-visible markings.

This process is largely done via two popular methods: Acid etching and laser etching. And while the end results of each are nearly identical on the surface, their effects on the end nameplate product and their development process are unique.

Acid etching, also known as chemical etching, is performed by using a chemical process that removes the thin layers of metal needed to produce your specific design.

When the acid etching is completed, your design will have tangible indentations according to where the metal was eaten away to produce the image.

If you’re aiming to produce metal nameplates on a large scale, chemically etching your nameplates is the perfect cost-effective solution. However, bear in mind that due to the nature of this mass production, your design and all of its accompanying information cannot be changed once the process has begun.

On the other side of the coin, laser etching provides a great way for marking variable information while maintaining a smooth, groove-free surface on your nameplate.

If there’s a small mistake in your information or design, you can quickly insert corrections due to the digital nature of the process, making it especially great for small quantities. Do note, however, that if you’re needing mass quantities produced, laser etching will often prove more costly than traditional chemical etching.

If your nameplates aren’t intended to be used in highly caustic or abrasive environments, wherein their information may be rendered illegible, etching is likely the best marking method for your nameplates.

Embossed Metal Nameplates

Embossing is the process of molding or stamping your design onto the nameplate so that its information stands out in relief from the rest of the metal.

Much like a military dog tag, for instance, your design protrudes from the surface, producing an informational display that’s both extremely visible and legible from multiple angles

A very durable form of marking your nameplates, embossing is a great fit for any nameplate that might see contact with extreme weather. When muddy conditions or heavy snow obscure other forms of marking, embossing helps your information stay visible in nearly any scenario.

Engraved Metal Nameplates

Whereas etching removes only a thin layer of metal, and embossing pushes your design above the surface of the metal, engraving cuts deep into the metal’s surface to carve your design directly out of the substrate.

Though typically more costly than embossing or etching, engraved metal nameplates are the most rugged, long-lasting means of displaying your information clearly and reliably.

If you’re a producer of any product that is designed for work in extreme environments, engraved nameplates are likely to provide the durability your product identification requires.

How Do Metal Nameplates Promote Your Company’s Brand and Benefit Your Marketing Strategy?

Though your industry may prohibit what type of visual elements can be represented on your product identification, adding your company’s branding to your metal nameplates can have a profound impact on your overall brand presence within your industry.

You reinforce consistency and recognizability in your branding.

Effective branding is all about consistency. From your customer service to your marketing, and even down to the components in your goods, everything you produce has an impact on how your brand is perceived.

Even though their impact might seem small, your nameplates play an important role in reinforcing your branding and maintaining a consistent and reliable presence within your target market.

When your customers see your products and read the information printed on the nameplate, they recognize your logo, your colors, your slogan, and other brand markers.

And this consistent recognizability is the key.

At a behavioral level, when people are consistently exposed to branding elements, such as brand colors, fonts, logos, and slogans, it acts as a subtle reassuring presence that makes them feel more confident in the quality of your product.

So even though they’re not physically large, your nameplates are a large part of your company’s brand presence and create more opportunities for you to further your brand’s recognizability and affirm within your customers that your products are the right choice.

You create strong correlations between your company, customer safety, and product quality.

If you’re a producer of durable goods, you know that the safety of your products is directly tied to your reputation both within your industry and among your target markets.

And when your customers are interacting with your product, one of the strongest signals of your product’s safety is the visibility and overall quality of your safety labeling.

In fact, according to the U.S. Product and Safety Commission, when customers aren’t able to easily notice safety information on a durable good, their trust in it and the brand who makes it significantly declines.

With both consumer safety and your brand’s reputation inextricably linked to the quality of your nameplates, it’s definitely worth the time to work with a product identification expert to ensure your nameplates are up to the level your customers expect.

Let’s work together to amplify your brand

I want to work with Lektron!Work With Lektron: The Leading Provider of Metal Nameplates

Though we’ve covered a lot of information together, the ultimate purpose of your brand’s metal nameplates is centered around 4 key goals:

- Ensuring the safety of your customers

- Keeping your products safe and accounted for

- Keeping your company in full legal compliance

- Amplifying your company’s branding and overall reputation

And with these focuses at the heart of every nameplate project we undertake, we’ve been fortunate to enjoy years of success in fulfilling our customers’ product identification needs.

We hope the information we’ve shared is useful, and if given the opportunity, we’d love to work with you, learn your specific product identification needs, and help you amplify your brand.

We can’t wait to meet you. Let’s get to work.

About Jeff Yowell

Jeff Yowell, Business Development Executive at Lektron Branding Solutions, helps brands across multiple industry sectors keep their customers safe, stay in compliance, and increase their market penetration through custom product identification solutions.

References

- Chang, Wei-Lun, and Hsieh-Liang Lin. “The Impact of Color Traits on Corporate Branding.” African Journal of Business Management, vol. 4, no. 15, 4 Nov. 2010, pp. 3344–3355.

- Lester A 2001. “Crime reduction through product design.” Trends & issues in crime and criminal justice. no. 206. Canberra: Australian Institute of Criminology.

- Mcgrath, John M. “The Role of Equipment Warning Labels in the Industrial Workplace.” International Journal of Occupational Safety and Ergonomics, vol. 17, no. 1, 2011, pp. 49–60., doi:10.1080/10803548.2011.11076871.

- Meis, Julia, and Yoshihisa Kashima. “Signage as a Tool for Behavioral Change: Direct and Indirect Routes to Understanding the Meaning of a Sign.” Plos One, vol. 12, no. 8, 2017, doi:10.1371/journal.pone.0182975.

- “Recall Effectiveness Research: A Review and Summary of the Literature on Consumer Motivation and Behavior.” PsycEXTRA Dataset, 2003, doi:10.1037/e442762005-001.